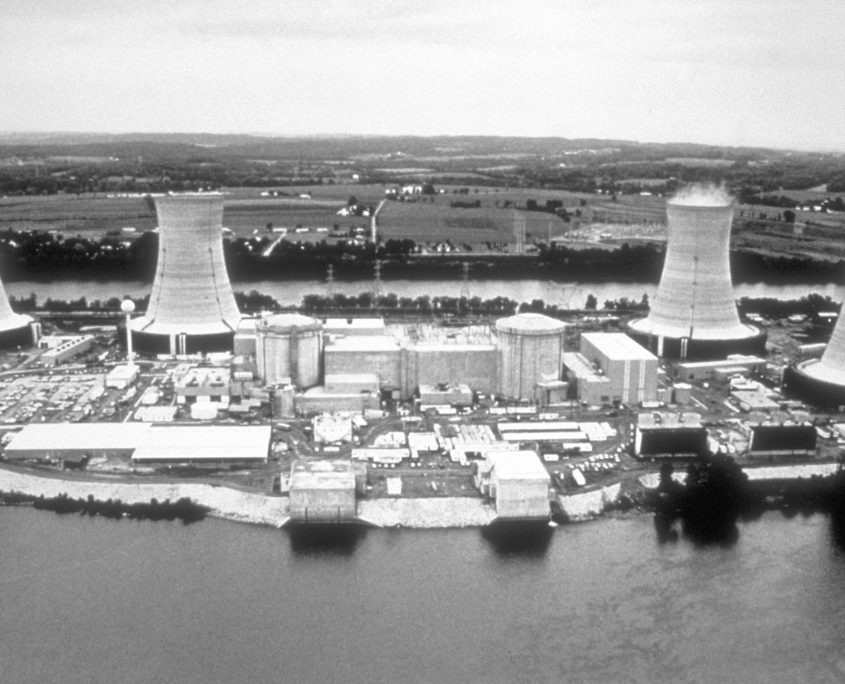

Nuclear Promise – Procedure and Work Instruction’s Perfect Storm – Part 2

Delivering the Nuclear Promise. As the industry changes and old processes are streamlined, the level of detail and elimination of human performance errors in technical documents becomes even more critical.

Part 2 – Nuclear Promise – Procedure and Work Instruction’s Perfect Storm

In Part 1 – Nuclear Promise – Procedure and Work Instruction’s Perfect Storm, I raised a concern based on my observation of challenges with regards to procedure and work instruction quality. These quality challenges include (but are not limited to): inconsistencies in level of detail resulting from staffing changes associated with the aging workforce and organizational and process changes resulting from executing efficiency bulletins associated with delivering the nuclear promise.

Procedures and Work Instructions are at a critical crossroads today. Impacts occurring from the aging workforce and implementation of efficiency bulletins supporting Delivery of the Nuclear Promise are impacting the availability of experienced/trained resources needed to keep thousands of procedures and work instructions up to date.

Preventing human performance errors in the field requires high quality “consistently developed” procedures and work instructions. For many years and in many cases today, the focus has been on technical adequacy and nuclear safety. As the industry has matured, it was identified that a technical and nuclear safety focus alone was not sufficient in preventing procedure and work instruction user human performance errors. Over time, it was discovered that the usability of a document can be even more of an error-likely situation than a stringent focus on technical adequacy. With support from the Electric Power Research Institute (EPRI), Institute of Nuclear Power Operations (INPO), Nuclear Energy Institute (NEI),and Procedure Professionals Association (PPA) standards have been developed to create a human factored focus in order to eliminate negative trends the industry has experienced.

Through my interactions while traveling (consulting training, advising), I have observed several challenges that are very concerning:

- The average years of experience of operations and maintenance staff is rapidly lowering.

- Work instructions and procedures used many times previously are now resulting in stopped work as a result of insufficient detail.

- Experienced staff that once pushed for instructions written at the “what-to-do” level of detail (in an effort ensure maximum flexibility) are now being replaced at a rapid rate with qualified yet inexperienced staff that demand a greater level of “how-to-do” detail.

- Even supervisors, although qualified, often do not have the experience to answer in-field questions without referencing documentation that is frequently vague and interpretive.

In addition, requests for new or changes to procedures and work instructions are being sent to smaller numbers of procedure writers and planners and in many cases the upkeep of these documents has been handed back to the line staff and process owners as a collateral duty, second only to their primary job function.

These individuals, although they are technically qualified in their specific work discipline, often do not have:

- Adequate computer skills (MS-Word). For example planners experienced in Passport, Maximo or SAP are being requested to write Level One work instructions in MS-Word. In some cases the staff is provided training on a company MS-Word Work Instruction template although the template training was insufficient as it was assumed the planners were proficient in MS-Word and many are not.

- Adequate training with regards to content an format requirements. Little or no training has been provided on a stations procedure and work instruction content and format requirements or in many cases no content and format requirements exist.

- Human performance focus. No training or guidance has been provided that focuses the procedure writers and planners on the elimination of human performance error-likely situations. Too often the staff finds what looks like a well written document and they make it look like that, creating issues where human performance errors are carried forward.

In conclusion, the writing of procedures and work instructions is a critical job, not one intended to be performed as a collateral duty. This is, perhaps, even more pertinent today than it has been in the past. Eliminating human performance errors requires consistency in document development. When untrained staff is tasked with document development as a collateral duty or a reduced number of existing staff are taxed with more work than they can reasonably perform, document quality will suffer and human performance errors will occur.

As the industry is changing and old “bloated” processes need to be streamlined and the level of detail and elimination of human performance errors in technical documents becomes even more critical, we must recognize the need for consistency in document development. Achieving the level of consistency needed to prevent human performance errors requires the qualification and support of trained dedicated procedure writers and planners.

Join us for an additional discussion of this issue in Part 3 – Nuclear Promise – Procedure and Work Instruction’s Perfect Storm. This final segment will focus on suggestions and creative ideas supported by existing industry guidance on how to eliminate the risk of human performance errors in procedures and work instructions in support of Delivering the Nuclear Promise.

If you like our content, subscribe to our blog using the link to the right of this post. Or, visit our services page for more information on our staffing, training, or consulting services.